Jewell

I am delighted to be the Australian builder for Francois Viviers gaff yawl Jewell and is the authorised supplier of CNC kits for Jewell ,and will be happy to supply complete or partial kits for other Vivier designs to costumers requirement.

Sea trials

All of Jewell's parts from hull frames to locker shelves as well as the building jig and molds are pre cut on our own cnc machine.

Jewell #4 under construction in Perth West Australia,

The cnc cut panels fit together easily, the slowest part of the process is sealing the frames before assembly as this is significantly faster and easier to do on the bench. Cleats for seats, lockers etc are also fitted now .

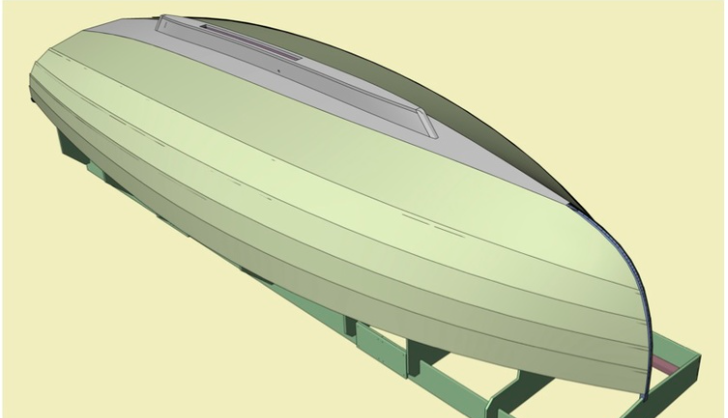

The use of cnc cut parts from a CAD program ensures a hull is constructed quickly and accurately.

O'Connor Wooden Boats. Unit 4, 12 Day rd. East Rockingham. 6168 Western Australia. Phone 08 95921826.

Mobile 0423 284502

A family friendly day boat, she has to meet the following main requirements:

- To be trailerable by an ordinary car, and therefore light, and be able to beach temporarily for loading/unloading.

- To have a large, wide and deep cockpit, comfortable, allowing for fishing and a place where children could be safe.

- To have a stable hull for family sailing but give excellent performance for weekend sails “with the guys”.

- To have a cuddy cabin, with a toilet for women and children, a small galley to heat some meals and two berths to spend a night or two on board, or for napping.

The use of cnc cut pieces has a significant impact on the building process, saving time transferring shapes from patterns or calculating shapes fro written dimensions. The accuracy of cnc cutting ensures that each piece is exactly the size it should be which can prevent a lot of head scratching and heartache later on.

"As a professional boatbuilder I am always conscious of the time (and therefore cost) of any work done, and I feel that the biggest advantage of cnc machining in professional boatbuilding is the savings in time, I have come to regard my cnc machine as an unpaid assistant who always does exactly what he is told to do."

"Another advantage with cnc cut kits is the efficient use of materials, with Francois Vivier kits each sheet of ply is optimised to produce the most efficient use of materials. I only use top quality Lloyds approved ply which is expensive so efficient use of materials is an extremely important consideration in my work."